Design guidelines

3D printing guidelines

3D printing with concrete is a very innovative technology that requires different ways of designing to ensure printability. Here you can find guidelines to help design suitably printable objects.

Object sizes

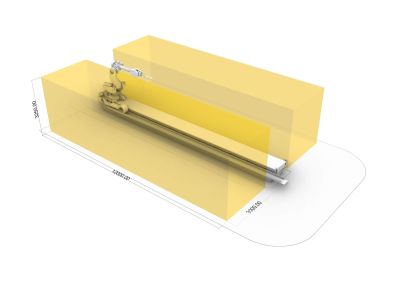

Printable Area

The 3D print factory has two print beds with maximum print area of (LxWxH) 12000 x 3000 x 3250 millimeters.

3DPF Maximum size

Maximum printable object

The most optimal objects for the 3D print factory should be no more than (LxWxH) 40000 x 1350 x 3250 millimeters with a maximum weight of 3000 kilograms. Objects within these parameters can be handled in house.

| Layer Width | Layer Height | Maximum unsupported overhang |

|---|---|---|

| 30 mm | 6 mm | 83° |

| 50 mm | 10 mm | 83° |

| 50 mm | 15 mm | 85,5° |

| 70 mm | 10 mm | 80,5° |

| 70 mm | 15 mm | 83,5° |

| 80 mm | 10 mm | 80,5° |

| 80 mm | 15 mm | 82,5° |

Print Path

Designing for 3D printing with concrete starts with being conscious of the print path. Designers should know what layer width their design needs. Doing this will ensure proper printing strategies, corners, interconnecting layers and overhangs.

Closed Loop

Traditional 3DCP designs are closed loops allowing for continuous print in a single direction.

Open Loop

Objects can also have open ended loops. In this case 3D printed layers would be built in alternating directions. This technique should be used sparingly.

Single Layer

Overlapping layers

Layers can also overlap each other other to make connections. This is useful with designing stairs for example. When doing so layers should overlap for a minimum of 5 millimeters in depth and 10 millimeters in length.

Overlapping Layers

Corners

Sharp corners

In traditional 3 DCP sharp corners are not possible.

Corners 3D printing

Rounded corners

3DCP produces rounded corners. Rounded print paths for corners should have a radius that is half of the layer width. For a layer width of 50 millimeters the radius should then be 25 millimeters.

Corners 3D printing

Printing strategies

Horizontal layering

Objects that have horizontal bottom and top layers can be sliced and printed in the traditional horizontal layers.

Horizontal layering

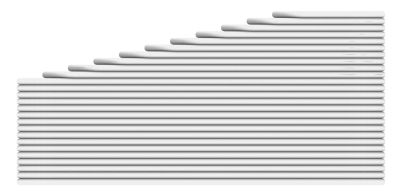

Stepwise layering

Angled top layers can be printed in a stepwise manner with horizontal layers

Stepwise printing

Non planar layering

Angled tops can also be produced using non-planar printing methods within certain parameters.

Non planar layering

Sectioning Objects

Objects exceeding the maximum size of the 3D Print Factory are still possible. The objects can be sectioned in the several elements than can be printed and assembled afterwards. These elements could also exceed the maximum weight if needed. These elements will then have to be moved by an external company.

Object Sectioning

Object Sectioning

Technical Specifications

| Standard lead time | Minimum of 7 working days depending on part size and curing time needed |

| Standard accuracy | ±10% |

| Surface structure | Unfinished parts typically have visible building layers on the surface |

| File formats | We accept file formats STL, 3DS, 3DM, 3MF, STP and SKP |